Our Presses

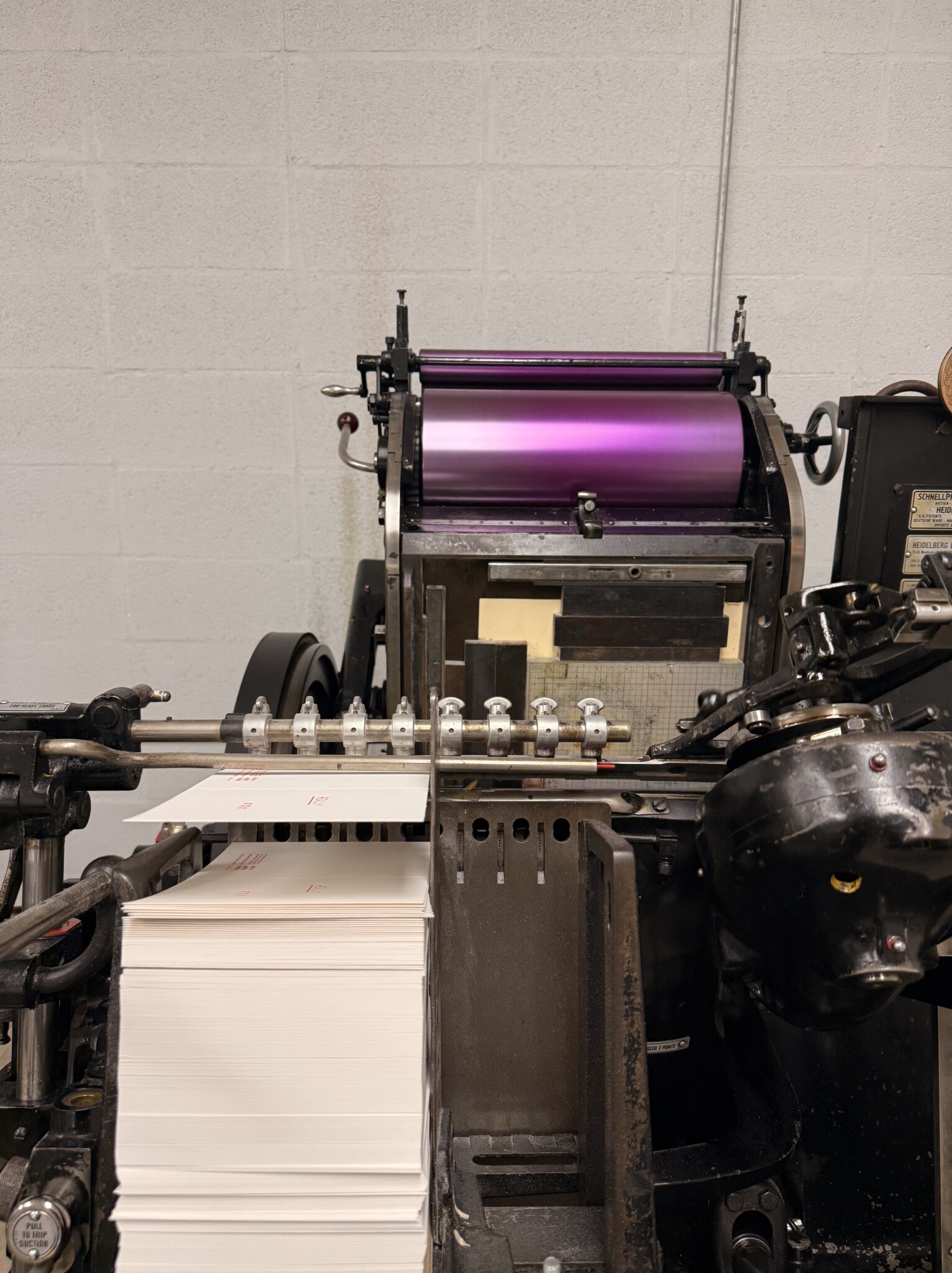

All INK MEETS PAPER cards are letterpress printed at our studio in charming Greenville, South Carolina. Our oldest press is a Chandler & Price platen press from 1896, and our youngest press is a Heidelberg Windmill from 1959. We love a good piece of antique equipment around here— they just don’t make ‘em like they used to!

Team INK Fun Fact:

Our first press was a 1,000-pound 8×12 Chandler & Price press that we purchased from a print shop in Jacksonville, FL. They were closing out the letterpress portion of their shop, so we’re happy to have given this press a new life! For many years, this was our only press, and each card was fed by hand, one color at a time. While not our daily-use press anymore, we still print with this press on a regular basis!